Project 2: Home Automation

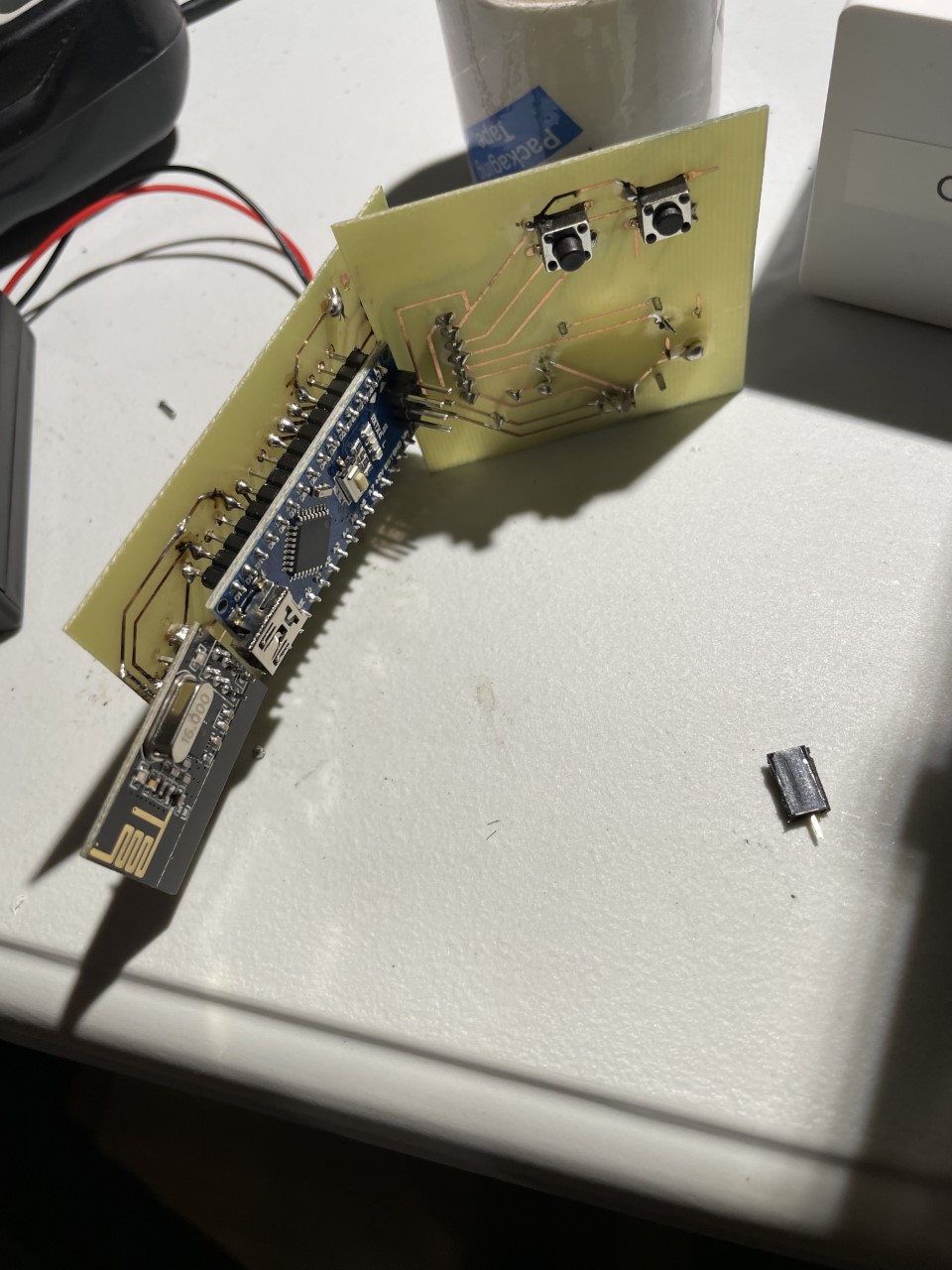

Lights

I wanted a way to control the main light in my room from a button or a voice command without interfering with the ability to use the light switch as normal. I decided to use a high torque servo controlled by an RF enabled arduino to flip the switch.

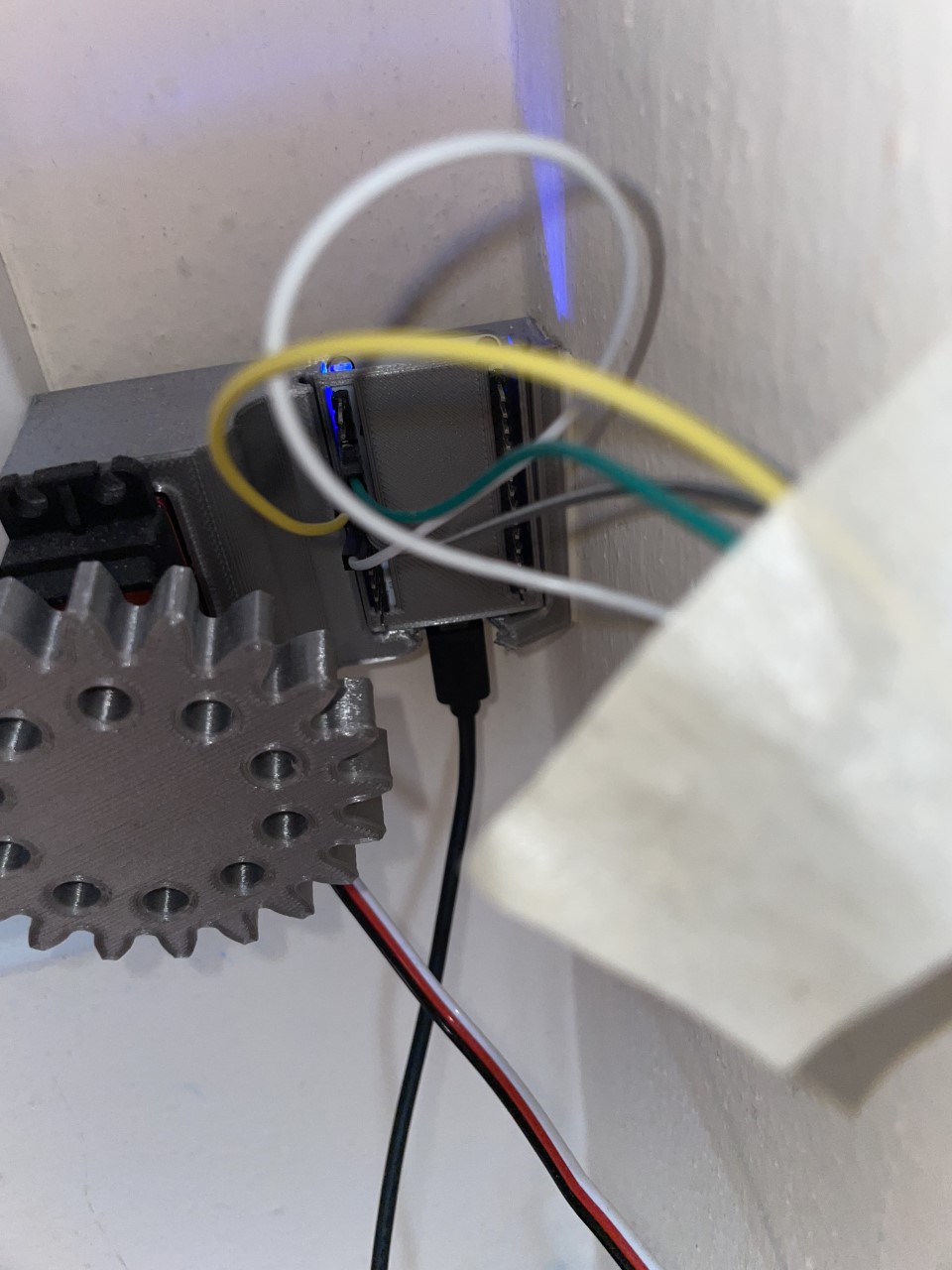

Heater

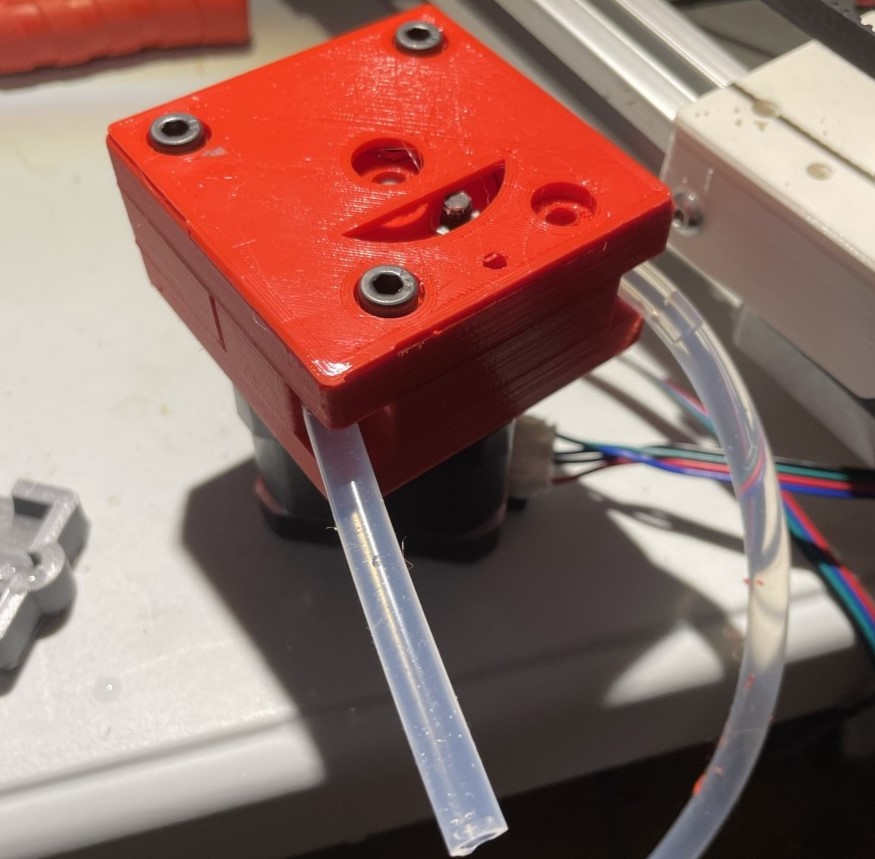

Living in Wisconsin during the winter means cold mornings. I wanted my wall mounted heater turn on a few hours before I woke each day so that I could wake up to a toasty room. Again using a high torque servo, I mated a printed gear to the servo and another to the knob on the heater, and controlled the position of the servo with an ESP8366

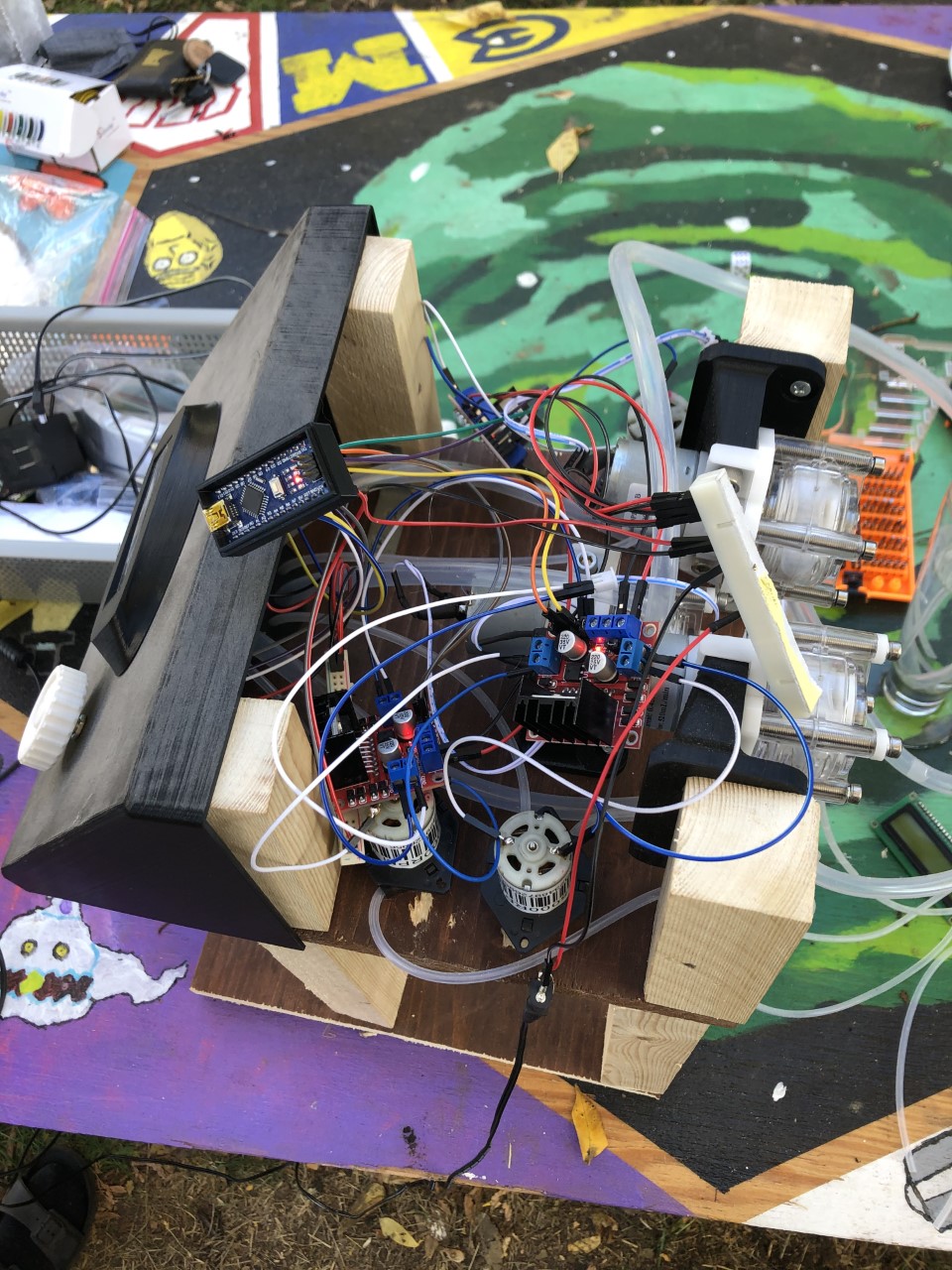

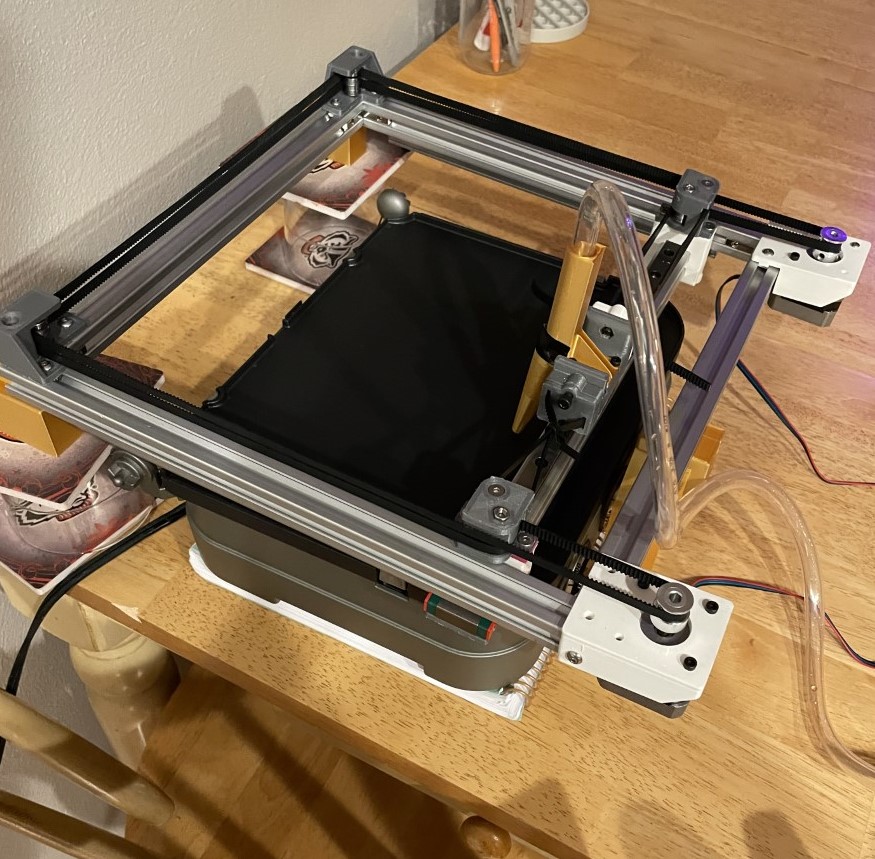

Decor

Finally, I linked all the previous automations to a central controller, in this case a photon. To capitalize more on the photon's capabilities, I made a laser-cut box with a painting by Bob Ross on the front, through with a set of LEDs could shine, creating a backlit painting. While I had the code, I also added LED strips throughout my room, all controlled by the photon.